|

||

|

|||||||||||||||

|

#1

|

|||

|

|||

|

If you have a 22 running in mid motor that you don't get on with, or you just want to make it better, then have a read of this thread as I've tried to summarise my last 4 months of development with the car to try and get to the bottom of why it is just doesn’t work out of the box.

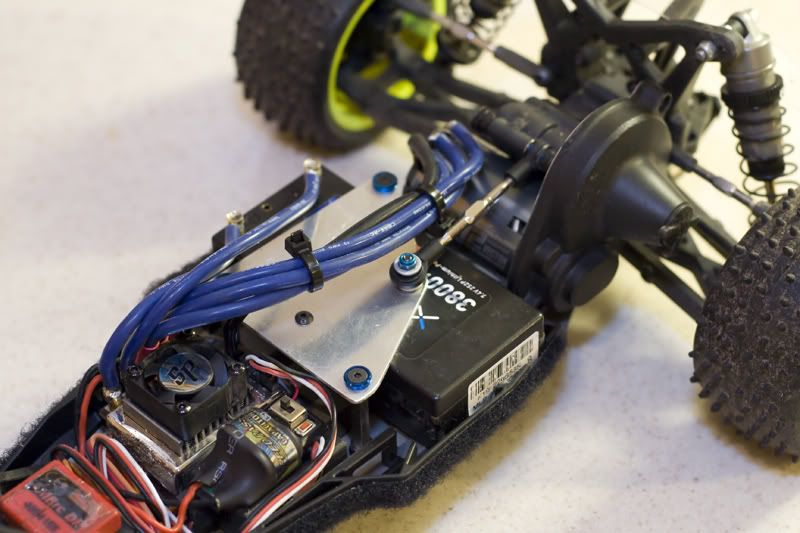

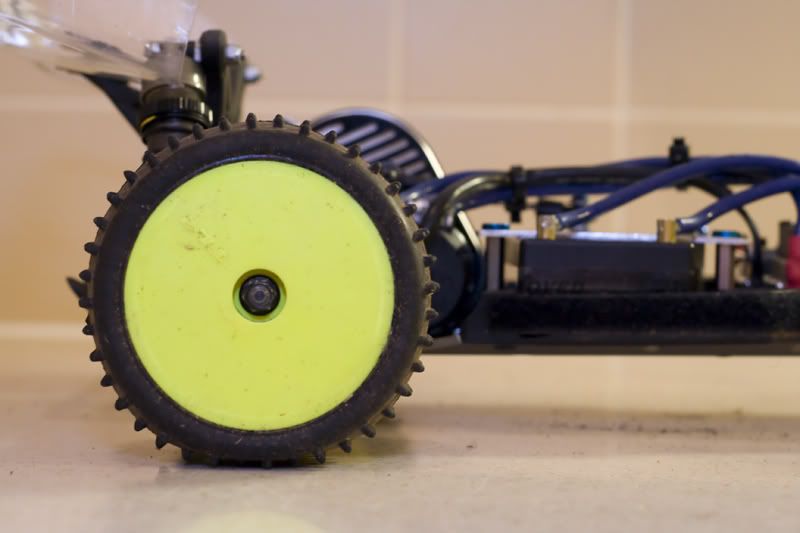

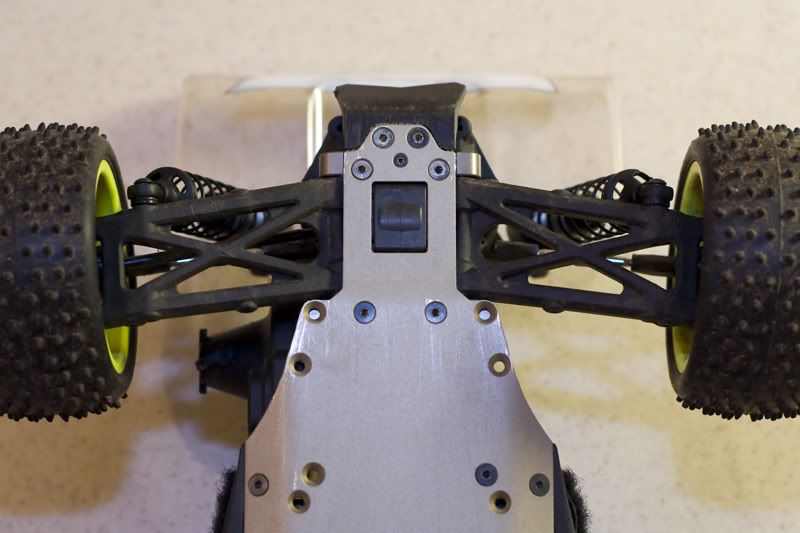

What this gives is a shortened 22 with the right wheelbase and weight distribution for about £10 in parts. To start with the standard mid motor 22 is a flawed design. It only works on very high grip surfaces with fast corners, as the grip lowers and the track gets tight and twisty it struggles with rear end traction as I think many have found, but also just isn’t quite fast enough, especially on rougher tracks. The most fundamental problem is weight distribution. The motor is too far forward in the wheel base and the batteries have the wrong orientation. The target for weight distribution of a mid motored car should be around 64% on the rear axle (based on X6 learning from Ellis and the C4.1) which is not dissimilar to a rear motor car but the speed advantages come from inertia and where the mass is placed. By taking lots of corner mass measurements I've found that a 22 built to kit form with saddles and the speedo upfront next to the servo has a weight distribution of 61% to 62% depending on the bits. Hang all the mid motor brass mass out the back (62g) and it gets up to about 63% to 63.5% and can get to 64% if the speedo is moved next to the motor and the wheelbase is shortened as much as possible on the rear hubs. Whilst this can deliver traction that is OK the car then has a big mass hanging out the back which starts to introduce the inertia effects you get on a rear motor car, so kind of defeats the object for a mid motor. Removing the rear mass the car is always nicer to drive and more consistent, but only if you have a high traction surface. Watching Tom with the C4.1 this year it carries speed but also delivers traction and is very good on the rougher ground so I decided to look at it in detail to try and figure out its secrets compared to the 22. Looking at the photos below the first thing is chassis flex. It has a single flat aluminium chassis with pivoted upper link. Basically it's quite flexible in twist across the rear axle and this is one of the things that helps deliver traction and ride. In comparison the 22 is very rigid, I did an experiment of removing the gearbox to chassis brace in the wet at the Ledbury regional and the car was more forgiving to drive with better traction. You do get unwanted flex front to back though so not ideal.  Second point is motor placement. If you look at the relative position of motor to rear wheels the C4.1 motor placement is about 15mm further back in the chassis than the 22 so obviously how it is getting better weight distribution. Looking into why it is so different to the 22 leads to a simple answer, it's because the rear arms sweep forwards on the C4.1 (and the X6 so nothing new here) and backwards on the 22. As I have a B4.1 awaiting a C conversion I compared the 22 and B4 rear arm geometry and was surprised to find they are identical, so the size, pivot points and sweep. This means if you swap the rear arms left to right on the 22 the motor is placed the same as the C4.1 relative to the rear wheels, plus the added advantage of the wheelbase shortening. Problem is the rear mount is then in the wrong place.   The sweep forward of the rear arms is obvious in this photo.  Other things I've noticed is that the C4.1 is effectively running the equivalent of a 22 LRC, and I've done LRC vs HRC 3 times now and LRC wins everytime for traction and stability. Another thing is overall wheelbase, the C4.1 is not short overall but is still about 275mm, compared to the 22 at 285mm. Also watching Tom's car on the scales he's been at 1650g when I've seen it, so a touch lighter than what the 22 can get away with. With all this in mind I've experimented with moving the batteries and adding a pivoted brace to allow flex which have all helped but still wanted to shorten the car but not by conversions I've seen as the motor is still in the wrong place. So after much head scratching I found a solution that allows the rear arms to be used on the opposite sides meaning they sweep forward. What this has achieved is a weight distribution of 64.2% without the mid motor brass out the back (and even including brass weight at the front), a shortened chassis wheelbase of 273mm and flex in twist across the rear axle. The car is absolutely transformed. I've run it on dry and wet astro and grass and it's both faster but also much more consistent. You can now power out of bends and feel the traction rather than wondering when it will swap ends, or waiting until it is straight before hitting the throttle. It also turns faster and is more direct yet safer at the same time and rides and jumps better. FTW body to fit the cell placement:  Shortened wheelbase of 273mm:  Pivoted upper brace, stumpy lipo across the chassis:   Motor relative to rear wheels much better than standard:  Arms sweep forward:  Rear tower and inner pivots moved forward:  Overall chassis:  And best of all it uses the original chassis and just needs a drill and some cutting and filing, plus some bits from maplin and a bit of aluminum, so about £10 in parts. I've tried crashing it a few times on the big jumps at Cov on purpose without breakage, also the rear driveshaft engagement is marginal but so far so good. Overall is shows how the mid motor 22 needs a different gearbox arrangement with idlers on the top of the diff and moved rear tower. I wonder if the C4.1 gearbox could be made to fit with it's rear tower... |

|

#2

|

|||

|

|||

|

Good work and info pookster

Did you flip the rear wishbones and leave as they are or shave them aswell to move forward in the inner hinge pin area ? |

|

#3

|

||||

|

||||

|

Have you got pictures of before and after of the rear toe-in or do you know how much it after the change?

just done some pics

__________________

o0ple Trader Feedback NE Venue's New & Old my space on YouTube CFR RCTV Channel Glenn Atterton BRCA 2005 1/10th Off-Road Veterans Champion LMP12 National Champion 2003/2004 / F3 class |

|

#4

|

|||

|

|||

|

If you want to do a step by step guide on how to do this ill buy you a beer or 3!

|

|

#5

|

||||

|

||||

|

I tried turning the arms around a few weeks ago and felt it was better but i had to use a spacer on the lower shock mount as they were binding on the tower.

looking at your pictures it looks like the shock tops are touching the tower, did you dremel or file them. I'm going Cov tonight and Sunday, wouldn't mind a look if your around? |

|

#6

|

|||

|

|||

|

Toe is unchanged as the arm pivots run parallel, so still 4 degrees with kit LRC toe block.

|

|

#7

|

|||

|

|||

|

Arms are standard. The offset between inner and outer pivots is 7mm so when you swap the arms the wheelbase shortens by 14mm. I did have the hub on full forwards with the standard arm position now have the hub fully rearwards with the swept forward arms.

|

|

#8

|

|||

|

|||

|

Quote:

Wont be at Cov on a Thursday in the near future I don't think. |

|

#9

|

|||

|

|||

|

Hi,

That looks great! How far forward did you move the shock tower and links? Also what did you use to mount that plate above the Lipo? Phil |

|

#10

|

||||

|

||||

Second point is motor placement. If you look at the relative position of motor to rear wheels the C4.1 motor placement is about 15mm further back in the chassis than the 22 so obviously how it is getting better weight distribution. Looking into why it is so different to the 22 leads to a simple answer, it's because the rear arms sweep forwards on the C4.1 (and the X6 so nothing new here) and backwards on the 22. As I have a B4.1 awaiting a C conversion I compared the 22 and B4 rear arm geometry and was surprised to find they are identical, so the size, pivot points and sweep. This means if you swap the rear arms left to right on the 22 the motor is placed the same as the C4.1 relative to the rear wheels, plus the added advantage of the wheelbase shortening. Problem is the rear mount is then in the wrong place.   The sweep forward of the rear arms is obvious in this photo.  Overall is shows how the mid motor 22 needs a different gearbox arrangement with idlers on the top of the diff and moved rear tower. I wonder if the C4.1 gearbox could be made to fit with it's rear tower...[/QUOTE] ORRRRR an even better solution would be to just buy a C4.1 in the first place............TEAM ASSOCIATED all the way

|

|

#11

|

|||

|

|||

|

Nice work, but you can achieve a wheelbase of 278mm with no mods at all, just move the rear hubs and arms full forward, and move the front hubs back in the arms ...

Also, if you hack up the side pods and place the lipos side by side, with around 30gms of lead under the back of the lipos and a brass hinge pin weight you can get around 65% rear weight bias .... I don't know if its the "solution" ... cos I've not had chance to try it yet  But I'm looking forward to tomorrow night ... |

|

#12

|

||||

|

||||

|

Quote:

__________________

Jonathan | Atomic-Carbon |

|

#13

|

||||

|

||||

|

I have day dreamed about taking the rear motor trans, and making the topshaft come out the right side once the motor is mounted in the mid position. This would be a lot of work, but it should keep the motor rotation right and move the more towards the back of the car. I have not tried mine mid motor and do not have the parts in front of me to confirm if this is even possible. I did this on a mid motor xxx oval car I made back in 2004 and it worked pretty good.

__________________

HB Team Driver| Viper RC | VP Pro | Speedzone | http://bjcaldwe.blogspot.com/ |

|

#14

|

||||

|

||||

|

The first time I saw the 22 in mid motor, the first thing I thought was, damn that motor is a long way forward!

I never really liked the rear weight either, since it should just give a horrible pendulum setup....not good. I have to say the conversion looks good, would be good to see full size saddles in there, next to each other like the c4.1 pictured. Nice conversion David! And Cheap! Good work, and well done on perservering with the 22.

__________________

:: AE B5MCE - SP 7.5 v3.0 Brushless Motor - Reedy Shorty Lipo - Savox Servo - Spektrum Rx :: :: Paint By Turnip Paint :: |

|

#15

|

|||

|

|||

|

A step by tep guide would be very nice. Does anyone know what the wheel base would be with the rear arms foward, rear hubs foward but front arms foward?

|

|

#16

|

|||

|

|||

|

With everything moved forward when in standard config you can get the wheelbase down to about 281mm depending on ride height.

In terms of how this car is going with this solution it's running very nicely, and still hasn't broken anything despite crashing into lots of things at Coventry, and sometimes on purpose. I'm now running with no added weight on the rear at all, so had already removed the TLR weight but have now removed the Cream weight I had as well, it still has more traction than it ever did in standard form. Will see how it goes at the regional on Sunday. |

|

#17

|

||||

|

||||

|

how does ride height effect wheelbase ????

__________________

CML DISTRIBUTION -SOUTHWESTRC -HPI - RUDEBITS - MR O FOAMS - LMR - ATOMIC CARBON -STARREGORSEHOLIDAYPARK - ICON RC

|

|

#18

|

||||

|

||||

|

As far as I can see, that would apply to all 2wd cars Dave, as the lower the front, the slightly further back the front wheels, but it isn't a static measurement.

I am still unconvinced by this solution, apart from maybe proving a point. The driveshaft sweep your achieving is quite severe.

__________________

dragon paints : team tekin : fusion hobbies :SCHUMACHER RACING : Nuclear R/C for all my sticky and slippery stuff - if it needs gluing or lubing, Nuclear RC is the man! |

|

#19

|

|||

|

|||

|

Because the wheelbase changes with ride height as the front wheels move backwards due to the arm inclination....

|

|

#20

|

|||

|

|||

|

Driveshaft angle is the main problem because the gearbox is not made for this arrangement, but the car is so much better than standard and they haven't popped out yet.

|

|

|

|