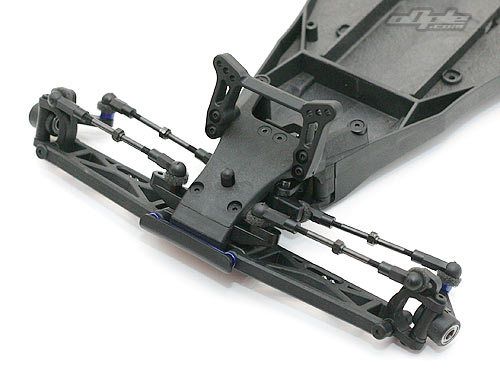

The front shock tower is a moulded plastic item and should take a lot of abuse if just for the fact that it is so small! This secures to the front top plate with four screws. This is probably a good time to mention the screws in the Ultima RB5 kit. Kyosho have clearly listened to the customers, and one of the main issues I pointed out on the ZX5 review was the poor quality phillips head screws. Thankfully the RB5 comes supplied with a full complement of hex-head screws.

|

|

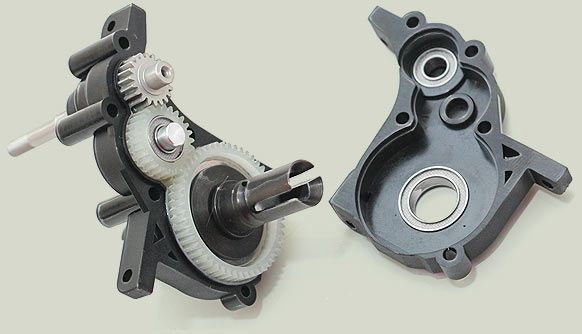

| The front end is fairly close to complete now so the attention turns to the rear end - starting with the 3 gear transmission. The transmission on the RB5 is very much like most 2WD buggies around currently, with three main gears - keeping it as simple as possible - An alloy top shaft, idler gear (spinning on an alloy shaft) and diff gear. The differential is first up and If you are familiar with either of the other two main buggies - you'll be at home with the RB5 that's for sure. |

|

The diff uses imperial balls, 3/38 for the main balls and 1/16 for the thrust balls. The balls in the ZX5 were known to be a tad soft, it's not clear whether these are the same.

The thrust bearing is of the individual balls and two hardened washers variety. A bit of a pain to build, but with plenty of black grease (supplied) and a scalpel, it's not too hard.

|

|

The RB5 differential has a neat feature. Instead of having to disassemble anything on the car to adjust the diff, it is possible to poke a driver through a hole in the left-hand diff half, which engages with the diff screw, and simply rotating the right hand wheel one way or the other will loosen / tighten the diff. Ok, there is nothing too new about that, but the hole used to lock the diff screw is protected with a small clip (which needs a section cutting out) and this seals up the hole and keeps the delicate thrust bearing nice and clean between adjustments.

In truth, this clip can be a bit of a pain to remove / reinstall, and can slow down diff adjustments to the point where it would have been easier to pop the drive shaft out and do it the old fashioned way. |

|

The manual suggests to apply some silicone diff grease (white / clear) to the gears. I went for some Tamiya ceramic grease, but either way is good.

The gears all push in easily to the gearbox half, with the idler spinning on an aluminium shaft.

The gearbox is in two halves and these come together and provide a good seal from dirt ingress.

A blue anodised alloy motor plate attaches to the gearbox via four long screws which also clamp the gearbox together. |

The slipper on the RB5 is very similar, or identical, to that on the ZX5. It's a dual pad design, with a keyed slipper pad locking into notches on either side of the spur gear. This is sandwiched between two alloy plates which are keyed to the lay shaft to stop them rotating. The pads clamp the slipper pads from either side and a nut and spring modulates the pressure and resulting slip.

Ok, that's the fancy way of explaining it, but if you are familiar with any modern buggy this design will already be well understood.

The spur gear has 78 teeth at true 48dp - nice to not have to chase around for rare pinions. Since the design is already similar to other cars, you can for instance easily swap the spur gear and associated pads for the spur and accompanying pads from a B4. |

|

|