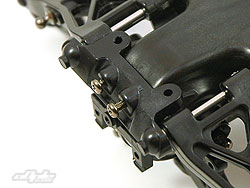

The steering on the Durga as already mentioned is a similar setup to that seen on its bigger brother – the TRF 501X. Although it’s slightly cheaper in construction it’s still a good design and feels solid when assembled. The twin bell cranks pivot on metal bushings but the steering bridge is still ball raced. |

|

| The assembled steering threads through the belt tunnel, and slips over the steering posts - finally being clamped in place with nyloc nuts. The steering is quite free until you press down on one of the arms – the sort of stresses that the steering would be under during racing, at which point the bushings don’t really ‘cut it’ and the friction ramps up. I added some grease to the pivots but some ball races would be a good upgrade in the future. |

The DB01 comes with 'Dog Bone' drive shafts rather than CVD or Universal Join type shafts. These should be one of the first upgrades to look at if you want to improve the durability of the car.

Orange foam spacers are inserted into the differential out drives to keep the dog bones in place. |

|

The Durga comes with the same steel turnbuckle camber links and plastic rod ends, as the TRF 501X. The turnbuckles are a slightly odd size and don't come with a tool for adjusting - I used a modified lunsford tool.

The turnbuckles are good though, and a very welcome feature on a car of this level.

The plastic ball cups / rod ends are good - they work well, but (from experience) with repeated disassembly from the ball they can become loose quickly. They just seem a little too soft and a hard sideways 'hit' can pop them off the balls - which is a little frustrating during a race. Indeed, oOple.com team driver Stu Wood had these fail twice at a National event which almost dropped him out of the A final with the 501X.

If you don't take the rods off too much - or replace them when worn, they are fine. For a car of this level though, they are great. The Tamiya factory team drivers seem to use a combination of HotBodies/Yokomo ball studs with Losi ball cups - so perhaps that gives an idea how they are seen by Tamiyas own drivers. |

|

|

|

| The Tamiya ball cups are BLING! |

Functional turnbuckles are a welcome feature |

The two foams press fairly hard on the drive shaft to keep it firmly in place. |

|

|

| Rear suspension arm (& 501X rear arm behind) |

Front suspension arm |

The suspension on the Durga is a near direct copy of that seen on the TRF 501X – which itself borrows heavily from the JConcepts BJ4we and others. Whilst the moulds are the same, the plastics used for the suspension arms is a new 'standard composite', not the carbon composite of the TRF car.

There’s no measureable difference in weight between these and the TRF items but there is just the slightest hint of flex, where the TRF arms have absolutely none. This could be a good thing of course – indeed at the 2007 World Championships in Japan, the Tamiya team drivers had their 501X suspension arms specially machined to give more flex, to aid in traction. |

|

The inner hinge pins pivot on plastic balls and are ‘captured’ by the chassis suspension mounts. The outer hinge pins are captured by a small screw in the ends of the suspension arms.

The kit settings for the rear suspension are long-long wheelbase. That means the hub is spaced back on the outer hinge pins, and the suspension arms themselves are spaced back on the inner hinge pins. This is adjustable by swapping around the spacers. The kit setting (the longest possible) should make for a predictable handling car at least.

The rear suspension mounts up with a rear hinge pin holder. This rear brace isn’t height adjustable, so anti-squat can’t be altered here. Shims are provided for the separate hinge pin holders at the front of the rear arms (which were installed at the beginning of the build) but these would give less anti-squat, not more.

|

|

With the rear hinge pins pushed into the chassis mounts, the rear brace pushes over the rear of the hinge pins to tie it all together nicely.

A small rear bumper caps it all off. |

|

The front suspension is once more a copy of the TRF 501X, which can only be a good thing. The main difference is the hub carriers now have a vertical ball stud instead of the horizontal on the original 501X - the 501X Worlds car uses alloy hubs with vertical ball studs. This allows the camber link height to be changed for different handling characteristics.

The steering knuckles pivot on king pins which screw through to the hub carriers. The TRF 501X had a slight binding issue here and I ended up drilling the hub carriers to get a nice free movement. With new parts I thought the Durga would be different – indeed the right hand assembled fine and was quite free with no real binding.

The left side was very stiff however, which I traced to the upper hole on the hub carrier not being formed correctly. I drilled this through with a 2.5mm bit, and the problem was solved. Given time I'm sure the steering would free-up naturally.

The front suspension arms are very beefy indeed, and even with the change in plastic from the 501X, these should hold up to just about any abuse. A plastic front brace holds the assembled front suspension together – this could be a problem area in a heavy crash, as it looks like the weakest point, until that is you add the front bumper. The front bumper acts like an additional hinge pin brace - wrapping around the original brace to give added strength. |

|

|

| The front brace attaches with two screws from the front. Two more screws go through the bumper & brace from below to really tie things together. |

|

|

|