The first step in the build is the transmission. The XX4 is designed to have the optimum weight distribution at its heart and the drivetrain is designed around this principal resulting in a rather complex arrangement of belts and pulleys which weave their way around and through the major components like motor and cells. It uses 3 belts in total to take drive from the centre of the car to front (1 belt) and rear (2 belts).

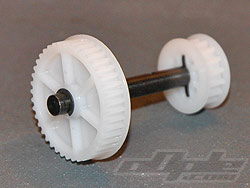

First up is the rear layshaft, a solid steel shaft which needs 2 pins pressing in which are used to engage a belt pulley at either end, one pulley takes drive from the centre belt and the other end transfers this to the long rear belt providing rear drive.

The spur / slipper shaft comes next in the build process, again a solid steel shaft which needs a small pin pressing through its centre which locates the front slipper plate.

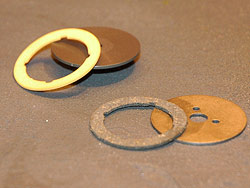

The slipper design is interesting, it’s a dual pad slipper with one slipper plate connected to the front wheels and one to the rear. You cant adjust slip to the front and rear independently but the Worlds Edition does come setup with a different pad for either side of the spur. The slipper pad and plate for the rear drive provides more friction than the front pad and slipper, thus enabling the rear to receive more torque before slipping occurs.

Some people use a modified front slipper plate and the corresponding pad for the rear which gives an even torque split.

I was advised at this point to swap the kit 84t spur gear (purple) for a smaller 82t (yellow) spur, this is im told to prevent the spur from touching the chassis under (very) heavy landings, this may not be necessary on the re-release but from what I’m told it is the choice of a lot of drivers anyway, it also pushes the motor forward slightly which will give a little more steering.

The rear slipper pad and plate go on after the spur, at this point you can clamp the two plates between your fingers and spin the spur gear, the front slipper will slip and the rear will probably grip, just an illustration of the different torque available to each end. |

|