The 410R was originally rumoured to come supplied with more typical ball-type differentials which you'll pretty much see on every other 2 & 4WD racing chassis these days. Whilst I was pretty interested to test the differences I'm also just as happy to find the 410R is instead supplied with the same sealed oil-filled gear differentials as it's big brother.

These gear-differentials have proven super robust in the previous car although not as entirely fit-and-forget as first thought since they will need re-filling occasionally - thankfully that's not a major job and it's not like a ball differential which all needs cleaning and setting/re-setting after a rebuild.

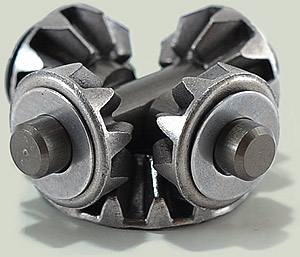

The differentials go together well - using plenty of the supplied grease on the input shafts and oil-seals. The main gears slide with slight difficulty onto the hexagonal-shaped input shafts - they actually go on easier than first impressions suggest since the more you try to force them on the harder it is. Getting the gears on properly so the input shaft is flush with the top of the gear is important to avoid excess play and help seal the diffs up properly.

Of course the beauty of the gear-differentials are the ability to fill them with different viscosity oils to tune their performance - commonly with a heavier oil up front and lighter in the rear. The kit-supplied oil is pretty thin and I wanted something a little thicker (a mistake probably given the first race I was going to take it to would be on a loose dirt surface). I went with 10K in the rear and 15K up front and marked the differentials cases so I knew which was which for when it came time to drop them into their respective gear cases. |