|

The X-6 is XFactorys take on what a modern two-wheel drive buggy should be like. Coming as it does, into a stagnant class wholly dominated by two large manufacturers, the X-6 certainly has its work cut out.

Standing out from the crowd should help the car get noticed, and the X-6 certainly does stand out, with an unconventional mid-motor design, 4+2 cell layout and radical aerodynamic looks.

The mid motor is, of course, the main design idea behind the creation of the X-6, with the motor placed just ahead of the rear wheels, rather than the more usual location –  hanging out back. hanging out back.

|

Many people will tell you the X-6 is bringing nothing new to the table, that there have been mid motor two-wheel drive buggys before. |

And, they are right. But only in so much as the original RC10 and the RC10-B4 are the same – clearly things have moved on, and so has the mid motor design.

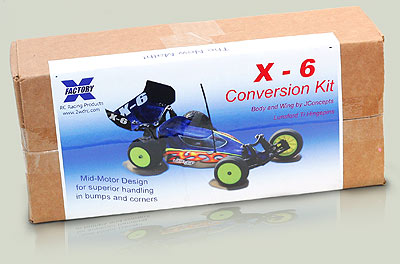

The X-6 is currently only available as a conversion kit for the Team Associated RC10 B4. Using the entire front end, gear box internals and shocks of the B4, along with some high quality moulded parts and a new body & wing package by JConcepts.

With the vast amount of B4 owners already out there, and with plenty of used cars for sale, the price of X-6 ownership shouldn’t be too high. The X-6 is ready to take on the race tracks of the world; excuse the cliché – but, let’s take a closer look. |

|

The contents of the X-6 conversion kit all laid out |

|

The X-6 comes packaged in the same small brown box as XFactorys X-5 conversion, with a sticker on top to identify the contents. It’s not the most visually pleasing packaging ever – but it's functional and keeps the contents safe.

Inside you are initially presented with a personalised sheet welcoming you to the XFactory family, along with a thick, printed manual and some stickers and window masks.

A variety of lettered bags contain the various stages of the build process. |

The chassis is moulded black carbon plastic and looks wider than it really is, possibly due to less narrowing toward the front like the B4 chassis has. Indeed, the chassis is no wider than that of the B4.

The bottom of the rear gearbox is moulded into the rear of the chassis and the kicked-up nose of the chassis is now a separate moulding from the main chassis, and is attached during the build.

The quality of the moulding is once more [X-5], very good, with the minimum of flashing. |

|

Things like the shock absorbers (if you are running the B4 items) and the differential are proably essential maintenance items so I gave these a clean - I rebuilt the front shocks with the same setup as my B4, for a starting point.

The CVD driveshafts from the B4 were nearly new anyway, but I still gave these a rebuild using Tamiya Anti-Wear grease. |

With the box open and manual in hand, the first steps are to disassemble the RC10 B4 donor car. The manual gets in depth with this process with many photos and step-by-step helpful advice and hints. It shows you what sort of parts to set aside for the X-6 build but if your car is "in a state" then it's likely you'll have to totally disassemble it and clean it all anyway.

|

The X-6 uses the rear hubs so I reassembled the CVDs onto the hubs and put them to one side. The rest of the front end was rather lazily washed in soapy water, sprayed with WD40 and then dried - lazy yes, but it works!

With an old box full of lumps of discarded B4, and a shiny pile of refurbished B4 parts waiting for their new home, it's time to look at the X6. |

|

|

|

Cleaned rear CVD ready for the grease! |

Rear hubs are used on the X6 |

The B4 gearbox in peices |

|