|

The steering on the BX is quite convential twin bell crank with built in servo saver. There are identical servo savers on both bell cranks however, which I have never seen before.

The bellcranks are linked together at the rear by a carbon link supported by flanged ball races, with a centre ball stud to the servo.

The servo savers act independantly for each wheel, I assume if one wheel takes a deflecting hit the other will keep tracking straight, I am also guessing that because there is one saver per wheel they can be a little looser putting less stress on parts and having a smoother action, just a guess though. |

A small corner of material needs taking off one of the bell cranks for clearance on the front drive belt.

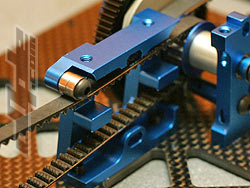

The steering rod assembly is next which consists of titanium turnbuckles with a slight groove on one side to show the normal threaded side. The ball cups as previously mentioned have holes for a hex driver and look really high quality. There is around a 4mm gap inside before the turnbuckle starts to thread in to the ball cup, this is to ensure the turnbuckle goes in straight before it starts to make thread.

A ball cup holder is moulded on the provided 4 way socket to aid in assembly but it is too small for these new ball cups.

|

|

A nice alloy turnbuckle wrench is supplied in the kit. I found the ball ends would pop off when adjusting the turnbuckles, I chose to ignore the advice in the manual to grease the threads before assembly so had to dismantle all turnbuckles and re do them with grease. Silly me.

The complete steering assembly is slid over the steering posts and screwed down until later in the build. |

The top half of the front gearbox is next, this consists of yet more blue anodised alloy which does the job of locating the eccentric bearing housings and holding the front shock tower.

The front belt tension is set by lining up a line on the eccentric housings with one of a series of lines machined into the lower part of the front gearbox. Once lined up (I went with kit settings) the top halves are screwed down to clamp it all together and finally clamp all the drive line down. |

|

|

|

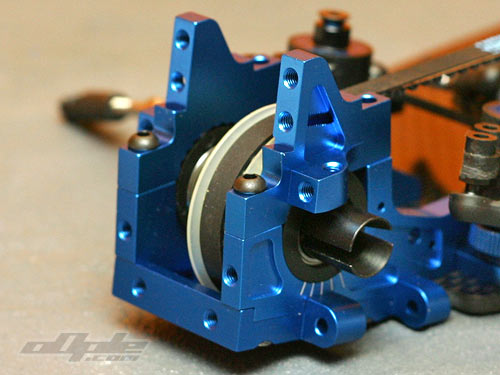

The motor mount is secured from below with 2 screws and is yet another work of machined alloy loveliness. It has the front belt running back and forth through it.

There is a belt roller utilising 2 tiny ball races to press on the front belt lightly, changing the angle of the belt to direct it around the motor and motor screws and adding a little tension. |

|

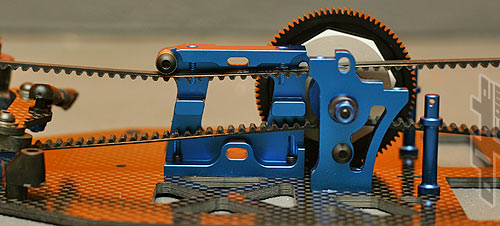

A second belt roller is provided, this consists of an alloy mount with 2 ball races separated by a plastic washer, the washer spaces the races correctly for the front and rear belts. The roller is mounted in such a way as to press lightly on belts and hold them against the centre pulleys.

The roller mounts in an elongated hole so pressure on the belts can be adjusted. The roller mounts under the lay shaft in the manual but another hole above the lay shaft appears to be an alternate mounting location. |

|

|

| The top deck for the BX is split into two with the front going front gearbox to centre, and the rear from centre to rear. Both sections are cut from 2mm carbon fibre. The front section of top deck is first prepared by adding the tops of the steering assembly and the front body mount, all in blue anodised alloy of course. 8 screws secure the front section and 4 the rear section of top decks. The top decks tie front and rear gearboxes, motor mount and centre layshaft mount all together. |

|

|

|

Motor mount with rollers |

Top decks front (top) and rear |

Front top deck detail |

With the belts and belt rollers all in place, the drivetrain was fairly stiff and though this would free up later after a couple of runs, I decided to set the front belt at its loosest setting and set the belt roller to just touch the belts.

The manual suggests installing motor and then servo at this point. I couldn’t really see a point as they would just get in the way so skipped this part until last as I’m sure most people will. |

|

The front shock tower is another thick (3.2mm) carbon affair with traditional camber link holes rather than vertical ball studs. |

|

Though the rear belt looks super close, it doesnt touch - until you go over a bump. |

|

|

Centre mount |

Front steering detail |

|