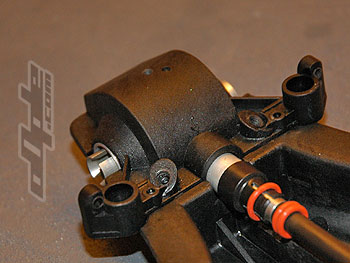

The front gearbox top has some holes which appear like they were drilled after the moulding, just like the main chassis has, these don't look overly pleasing to the eye with material proud of the hole they look a little messy.

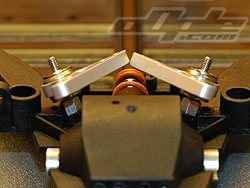

I already knew my front gearbox top was incorrectly drilled, because the rockers which transfer the suspension movement to the inboard shocks, collided half way though their travel. (Left: middle photo).

I sent the offending part back to TTech for a replacement, and manage to borrow a new gearbox top from a fellow racer and predator expert, Graham North.

This was much better, the front rockers now had a good mm or more gap. The pins that the rockers sit on (top right) were both "finger pressure" all the way in, these holes are very loose, I tightened as much as i dared. (more in the test race about this)

The screws clamping the gearbox together were not so easy to put through this gearbox top, you couldn't attach and screw them in one at a time as they wouldn't then line up and the other screws were impossible to insert. I had to put all 3 screws in with the gearbox top hovering above the chassis, then and only then could I screw them down. The holes just seemed out of line with each other very slightly. Seemed fine when screwed together. |