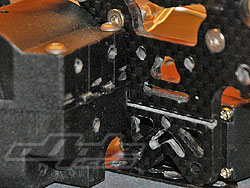

The rear large shock mount is next, and requires the anti roll bar and wing mounts screwing on before being fitted to the car, the carbon is thick at 3mm and with the low profile should be very strong.

There was a problem on my car here, the

rear gearbox top has a lug which helps locate the rear shock tower, it basically pokes out into a corresponding slot in the carbon tower.

Basically the holes and lug on the tower were slightly differently spaced

to the screws holes and slot on the tower. The difference was only around

half a mm, but it meant I either put the screws in first and crushed the

lug, or located the tower first on the lug and then wasn't able to screw it

down as the holes didn't line up.

I filed the lugs and the inside face of the slot on the tower, this enabled the tower to finally sit flat like its meant to. |

|

Although I mentioned the lack of lugs to locate the gearbox halves together, lugs are only good if they are in the correct place.

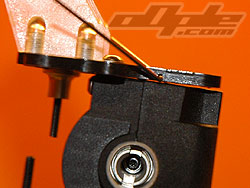

The wing mounts look odd compared to everything else on the car, they look

cheap as a first impression, the clear plastic doesn't seem to belong to

the rest of the car, they are fairly flexible though and seem like the

could take some abuse. |

|

|

| Shock tower wouldn't sit flat. |

|

| Rear tower and transparent wing mounts. |

|

|

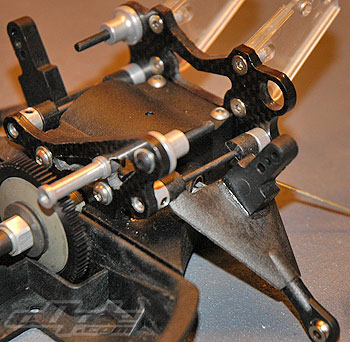

The rear suspension is of a “double wishbone” type, not the usual lower wishbone and upper camber rod, camber can be adjusted to a small extent via the hub, it has a elongated hole which the upper arm slides within, clamping down a screw and nut secures the camber change.

The wishbones use hinge pins inboard and ball joints at the hub, the lower arms have an adjustable rod which connects the hub and wishbone to provide adjustable toe-in. This is fine if you have the ability / tools to set up the toe in, but likely would confuse some people and lead to some un-equal toe settings.

The top wishbones need to have a shock mount secured to the top by 2 screws, here the manual also suggests running a small bead of thin CA glue around the mount to stop it moving. I cant quite see why this cant just be moulded as part of the upper arm, it would surely make it more accurate, lighter and with 2 Titanium screws, also cheaper.

The top hingepin is quite thin and runs between two alloy bushes which sit inside the opposing carbon towers. the wire is held into the alloy bushes with a grub screw. |

The grub screws are the last to be tightened after its all put together. Its also best for the grub screws to be level (with each other) otherwise the hingepin can sit at a different angle inside the bushes and bind the suspension.

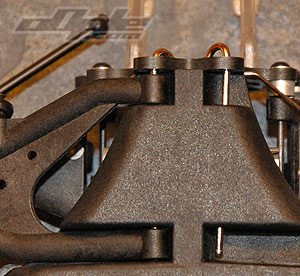

The lower rear wishbones are supported by one intricately bent hinge pin which goes through the rear shock tower and the chassis acts as the hinge pin block, supporting the pin behind and in the centre of the wishbone. The left side lower arm wouldn't fall under its own weight, I took it apart again and the holes in the arm where the hinge pin goes were slightly out, the angle on one side wasn't a direct line to the other side, I ran the hinge pin through a few times, same with the chassis, and upon reassembly everything was fine.

The lower arms hold the hubs, one side with a rigid ball joint and the other side with an adjustable rod which enabled unlimited adjustment of rear toe settings. The large ball joints on the lower wishbones are quite stiff and the

smaller ones on the toe-adjusters are quite loose and are quite easy to pop

off with very little force, I'm not sure if this is a problem when racing

the car but to stop them coming off completely I made sure all the open

sides faced outwards (so it can only fall inwards). |

|

|