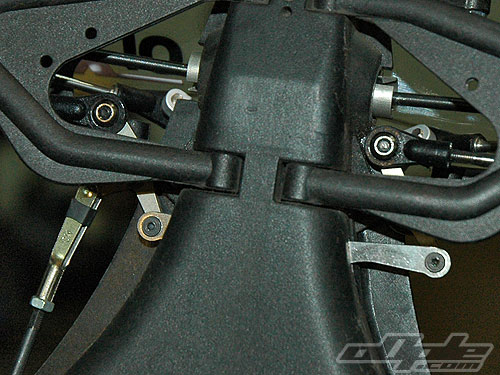

The shocks front and rear are identical and utilize short hard anodised

alloy bodies, dual rate springs (rear only), rebound valves (front only),

foam volume compensators and titanium nitride coated shafts. Only one O

ring per shock is used to cut down on sticktion. The shocks are not

threaded for height adjustment / preload but use clip on plastic spacers.

The O-rings supplied in the kit were, frankly, no good. I got the car new

and already the shocks were leaking. The O rings appear to be made from a

hard rubber rather than silicone, despite only having one per shock they

are far from stiction free.

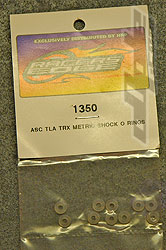

I purchased a set of Racers Edge metric silicone O rings and rebuilt the shocks with these. They are not quite as free (loose) but are much more “buttery smooth” and shouldn’t leak quite as easily fingers crossed.

TTech already offer upgrades to the kit Orings which I would guess are similar to the racers edge ones I used, mine came 10 to a pack, Ttech only supply 4 in a pack.

Springs front and rear are quite soft and the car can bottom out with a drop of only a few inches, this is something TTech are adressing with new springs coming soon. |

|

The spacer that goes between the O ring and the C-clip is vital to get the right way round, it took me a while to see in my dimly lit cellar that there was one side more open than the other, its very hard to see honest!

The Ti Nitride shock shafts are a nice gold colour like all the similar shafts on other makes of cars and those from MIP. While all those others are highly polished, the shafts in the X10 appear slightly dull and with a hint of texture when you run a fingernail down them, I’m not sure if this is important, part of the design or just a dodgy batch, with the racers edge seals there was no hint of leaking and they were smooth feeling so I guess its ok. |

|

The front shocks use a flat flexible disk under the piston, which Ttech describe as a “rebound valve”, the general idea of this seems to be to allow the shocks to react quicker to hits on compression but on rebound the disc would then block the hole in the piston slowing the return slightly. Some people seem to be either taking this off or using it on the other way around, at the top of the piston, slowing the compression and speeding up the rebound, either way its another tuning option.

Filling and bleeding the shocks is quite a nice experience, you simply fill the body with oil, screw on the bottom with piston etc, loosen off a turn and slowly push the piston all the way in, nipping the bottom tight when the piston is all the way in. This took all the air out and the shocks were very smooth and air free. |

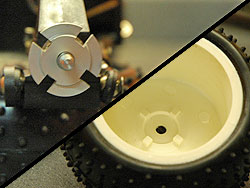

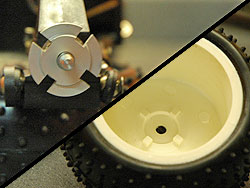

The wheels are a white dished design unique to TTech, they have 4 lugs

which mesh with the drive adaptors, referred to by TTech as

"X-Drive". Speaking to Tom Yardy (TTech team driver) the wheels are

unfortunately not compatible with Acetone (to remove old tyres), they will

melt. It is also apparent the wheels are more brittle than similar wheels

from others. They are at least cheaper than most other makers wheels and

are also available in bulk.

Wheels mount up perfectly true and wobble-free on the large adaptors unlike

most other manufactrers wheels.

|

|

| X Drive adaptor and wheel. |

|

|